|

Laminating Equipment and Supplies

|

|

|

ProLam Plus 330 Dual Head System

- Heavy Duty

-

Crystal-Clear Lamination

- Photo Ready

- Easy to use

|

|

|

|

|

|

ALM3220 Auto Laminator

The ALM3220 is a breakthrough in laminating

technology. Laminating has never been so fast and easy. Fujipla's

revolutionary compact auto laminator is as easy to use as a copy machine

and warms up in 5 minutes. Just load from 1 to 200 documents in the

automatic feeder and press the start button. Each document is

automatically fed into the laminator, laminated with the special

lamination film, trimmed to size and then stacked on the collection

tray. The ALM3220 can adjust to different size documents up to 12” x 18”

and can adjusted to trim with or without a margin. The

special AL laminating film comes in 1.5, 3 or 5 mil thickness in gloss

or matte finish.

-

Small foot print - less than 3 sq. ft.

-

Portable - locking roller casters

-

Ultra quick warm up of less than 5 minutes

-

Automatically feeds up to 200 sheets

-

Automatic two side lamination

|

|

|

|

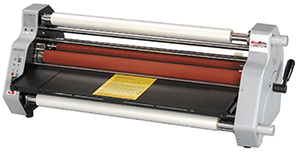

Lamrite 2700 Features

Heated silicon rollers - Rollers apply heat and pressure for a

superior lamination seal with none of the scratching found on heat shoe

machines

27" Width - Perfect for sheet size and

items as large as posters, inkjet prints, signage

Film thickness from 1.5 mil to 10.0 mil -

Utilizes film gauges for a broad range of applications and finishing

requirements

Variable speed & temperature control - Important for running

special films or unique product

Mounting - Up to ¼" Foam Core

Auto standby and shut off feature - Machine goes to standby in 60

minutes, complete shutdown shut down 30 minutes later.

Safety feed tray and front shield sensors - Machine will not

operate unless engaged.

Memory function - Common jobs can be stored into memory for easy

recall

Rear film slitter - Cuts film cleanly

avoids tearing finished product.

Proven Technology

Engineered for productivity, the 27" LamRite-2700

Roll Laminator delivers superior results at laminating speeds up to 8.8

ft / minute and can be used with fi lms up to 10 mil thick. Simple to

operate and perfect for Schools, Copy Shops and In-Plant centers.

Standard features include variable speed / temperature and tension

control for enhanced reliability, while the temperature memory function

maximizes repeatability. Auto shut off and front shield sensors provide

additional safety assurance.

With all metal construction, UL listing and a one year warranty, the

LamRite-2700 is unmatched in its class for value and performance.

Specifications:

Film core size: 1"

Speed: up to 8.8'/minute

Heavy duty all metal construction

UL listed

One year Warranty

Dimensions: 36.5" (L) x 14" (W) x 14" (H)

Weight: Gross weight 113 lbs.

Net weight 97 lbs

|

|

|

|

the Educator

25–inch

School Laminator

Ledco asked teachers and media specialists what they

wanted to see in a laminator and that's what they told us. So that's

what Ledco designed into the Educator. They started with the Graphic III

and Premier III machines that so many schools have learned to know and

trust for their laminating quality and trouble-free operation. Then they

simplified the controls and created an improved film path to eliminate

many of the operator errors common to thermal laminators. Posters, dry

erase charts, flash cards, bulletin board graphics, games, visuals and

teaching aids of all kinds represent a tremendous investment, whether

they were purchased, or made by teachers. Protecting and enhancing these

educational materials with lamination allows them to last for years

instead of being replaced every few weeks or months.

|

|

|

|

PREMIER 4

25–inch Commercial Laminator

The Premier 4 represents an evolution in mid-range

commercial laminators, because it includes so many features not

available on other laminators at any price. Whether it's judged by

appearance, by ease of use, by reliability, by the finished lamination,

or by overall capabilities, the Premier 4 represents quality and

versatility. Commercial users must have that quality to help them

satisfy their customers. The Premier 4 was made for copy shops, print

shops, business service centers, laminating services, school supply

stores, sign/banner shops, in-house graphics departments, 24-inch color

inkjet owners, and other commercial users with similar needs.

|

Standard Features

-

Variable Speed. Operates at any

speed up to 10 feet per minute. Thicker films are generally applied

better at mid-range to lower speeds, while 1.5 mil film should be

applied at mid-range to higher speeds

-

Digital LCD temperature display. Makes

it easy to set and maintain the correct temperature. The indicator

light inside the heat switch comes on as the machine warms up; at

set temperature the indicator light turns off.

-

Simple controls. Conveniently

placed switches provide a compact, reliable control pad. Icons and

international symbols are used for controls and safety warnings.

-

Slitters. Experts know the value

of slitters for laminating a quantity of same-size sheets. The

slitters remove the side scrap from both sides of each sheet as it

goes through the laminator. This greatly reduces the amount of time

required for trimming.

-

Swing-away heat shoes. This

helpful feature makes it much easier to clean the laminating

rollers. The Premier 4 is the only machine in its class to have

swing-away heating.

-

Easy threading. Threading can be

the most difficult aspect of using a laminator, so the Premier 4 has

built-in threading aids. The top idler is guarded from the top heat

shoe for safety and easy threading. The bottom idler is attached to

the feed tray. Once the upper and lower webs of film have been run

through the machine, bottom idler threading is automatic when the

operator puts the feed tray on the machine.

-

Forced air cooling. Allows

laminating with thicker films. Without a cooling system, thicker

films will warp or ripple because they are still too hot when they

come out the back of the laminator. The Premier 4 has a more

effective cooling system than any other machine in its class. There

are four fans in a 25-inch machine.

-

Ease of cleaning. The silicone

rubber rollers and the teflon-coated heat shoes of the laminator

should be cleaned regularly. The heat shoes on the Premier 4 swing

away in seconds, making it far easier to clean the laminating

rollers.

-

Attached safety shield. The

polycarbonate shield is clear so operators can see their work. It

does not conduct heat, protecting them from hot areas. It's fixed to

the machine and placed so they'll naturally put it in the guard

position before laminating.

-

Supply roll tension controls. Supply

roll tension is easy to adjust by simply tightening or loosening the

tension control knobs on the supply roll mandrels.

-

Ease of maintenance. The premier

4 is made to last. However, some items on a laminator do wear out.

Even the high-quality silicone rubber used in the rollers loses

flexibility over time. Extensive use may wear out the rollers or an

operator may cut a roller by accident. Rollers and other key parts

can be changed quickly without disassembling the frame

-

Reverse. Can be invaluable at

times to help avoid problems or remove misfed material. · Right

and left adjustable feed guides. · 100% Made in the U.S.A.

One-year warranty.

|

|

|

Digital 42 & 60

Laminators

User-Friendly Big Format Laminating and Mounting

These 42 and 60-inch wide machines were the first

designed exclusively for the owners of 36 and 50 inch inkjet printers.

They do all the finishing tasks required of a large format imaging shop

- laminating one side or two, encapsulating, mounting with heat

activated (dry mount) or cold pressure-sensitive adhesives (PSA),

simultaneous mounting and laminating, and application of cold adhesives.

These machines were made to be very easy to use,

incorporating many of the glitch-proof features we developed over 40

years of making laminators for schools and commercial finishing shops.

These units will laminate one item, then mount and laminate the next in

one pass on mounting board up to 1/2 inch thick. No setup change is

needed. In fact, you can laminate one item, then mount and laminate the

next in one pass without even stopping the machine.

With a top speed of 30 FPM and a sustainable

laminating speed of 10 FPM with 5-mil film, the Ledco Digitals are much

faster than the other machines made for big format color applications.

An optional release liner takeup allows the Digital 42 & Digital 60 to

apply cold laminating films, vinyls and other PSA materials needing

removal of a liner.

Standard features on both machines include variable

speed, independent top and bottom heat control, spacious feed tray,

powerful film cooling system, and swing-away heating units for cold

applications and easy cleaning of the rollers. |

Ledco's new patented ThermoGlide TM option is

available on both units.

ThermoGlide TM combines the best features of hot shoes

and hot rollers to produce the next generation of thermal laminating

technology.

Ledco is known for making machines that are very

reliable, easy to use, and inexpensive to maintain. These units maintain

that reputation. They come with a one-year factory warranty.

They are shipped fully assembled with a helpful

operator's manual and a 90-minute instructional videotape. Ledco

provides a toll-free help line to back up the training and support

required of its dealers. Customers are encouraged to call so that small

problems do not become big ones.

Standard Features and Benefits

-

Quality Silicone Rubber Laminating Rollers -

release materials easily and maintain their flexibility for a good

edge seal.

-

Interchangeable Laminating Rolls - Allow the

laminating rolls to be replaced with the pull rolls. If the heated

rubber rolls found on competitive laminators become nicked, they

require a costly replacement and down time.

-

Supply Roll Tension - is easy to adjust by simply

tightening or loosening the tension control knobs on the supply roll

mandrels.

-

Variable Speed - allows thinner films to be run

faster, and enables mounting or the use of thicker films, which

require slower speeds.

-

Independent Temperature Controls - for top and

bottom heaters allow the use of different materials on front and

back of an image.

-

Large Feed Tray - makes it easier to handle big

graphics. The pressure strip next to the nip helps keep images flat

and wrinkle-free.

-

Swing Away Heaters - make it very easy to clean

the laminating rollers and simplify the use of many cold materials.

-

Made In the USA

|

|

|